- Büyük Kayacık Mah. Org. San. Böl. 102. Cad. No:10 Selçuklu/Konya/TÜRKİYE

- +90 332 345 07 70

- +90 332 345 07 72

- bilgi@altundokum.com.tr

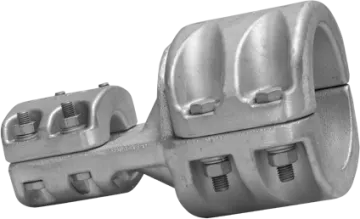

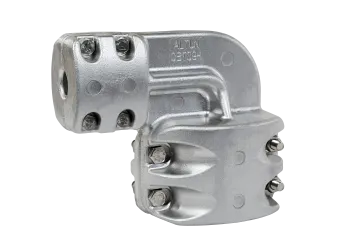

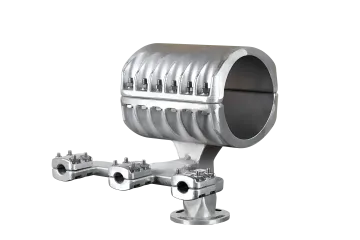

TUBE CABLE CONNECTORS

Tube Cable Connectors

These are the terminal blocks that are produced in pipe and conductor sizes suitable for the project, connecting the pipe busbar and conductor, connecting the pipe bar and the device. There are straight, angled, footed, t type tube cable conntectors models.

Durability of Connectors

While grounding in overhead lines, internal and external factors such as earth resistance, cable selection, voltage calculations are evaluated, and all conductive cables are collected and connected to each other with connectors blocks for pulling the cable during laying. Care must be taken to ensure that the tensile force that will occur during this process does not exceed 5 kg/mm2 for copper cables and 3 kg/mm2 for aluminum cables. Terminal blocks should be chosen in accordance with the needs and usage.

Terminal blocks can be produced in accordance with their usage areas. Terminal blocks in the carrier role must be able to resist up to three times the external load forces that may cause breakage and must also have the capacity to carry the combined pulling force. At the same time, the connectors that allow the cables to be connected with chain insulators and are subjected to tensile force should show a resistance between about three times the tensile force and less than 90% of the breaking force.

!['.$Settings->MainMeta['title'].'](assets/site/images/logo.webp)